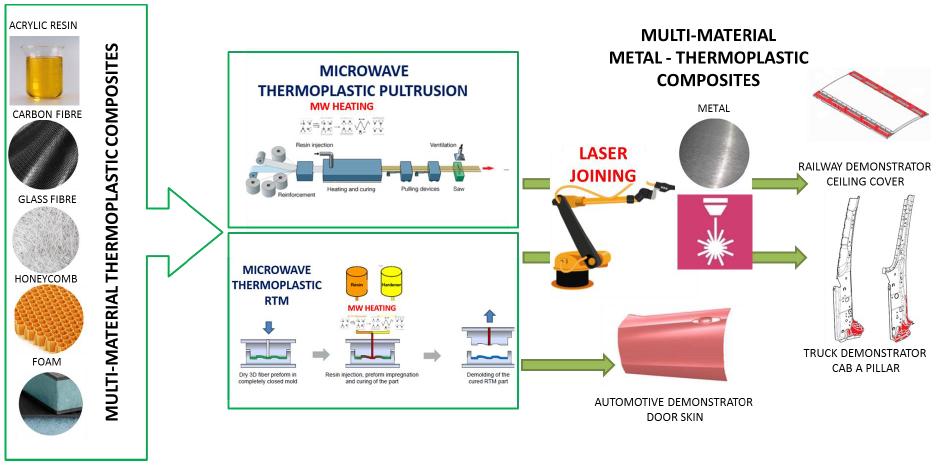

RECOTRANS project is a EC-funded project that will integrate unconventional manufacturing technologies such as (microwave) MW radiation and laser joining in current RTM and pultrusion production lines to be able to obtain cost-effective recyclable multi-material composites suitable for the transport sector at high production rates; 2 m/min for pultrusion and 2 min/cycle for RTM, reducing cost and energy consumption compared to current composites materials.To overcome these limitations, RECOTRANS project aims to integrate two unconventional manufacturing technologies (MW and laser joining) into two composites production lines (RTM and pultrusion) to obtain multi-material thermoplastic composites as an ideal option to move forward to zero-emission vehicles. Synthesites will contribute in the process monitoring and process control in order to ensure quality and industrial perfomance.

Recotrans project is led by AIMPLAS (ES) with partners:STADLER RAIL VALENCIA S.A.U. (STAV), AUTOTECH ENGINEERING – AIE (GESTAMP),Mercedes Benz Türk A.Ş.(MBT) , ARKEMA Innovative Chemistry (ARKEMA), INEA INFORMATIZACIJA ENERGETIKA AVTOMATIZACIJA DOO (INEA), TECNOCLAD LASER SOLUTIONS SL. (TECNOCLAD), FAR-UK (FAR), Fundación para la Promoción de la Innovación, Investigación y Desarrollo en la Industria de Automoción de Galicia (CTAG), İstanbul Technical University (İTÜ), Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. (FHG) and POLYMEC SL (POLYMEC).