- Company

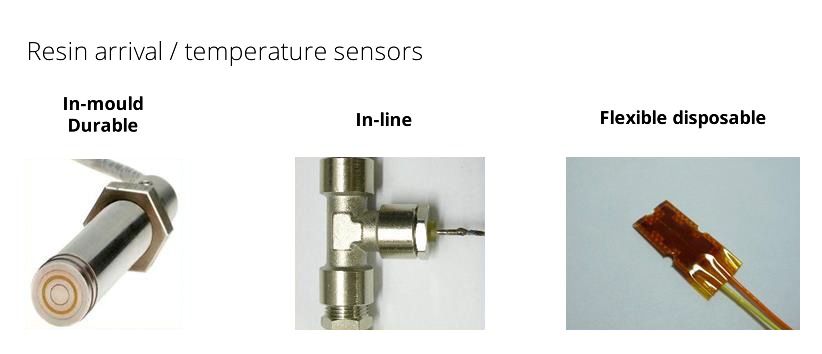

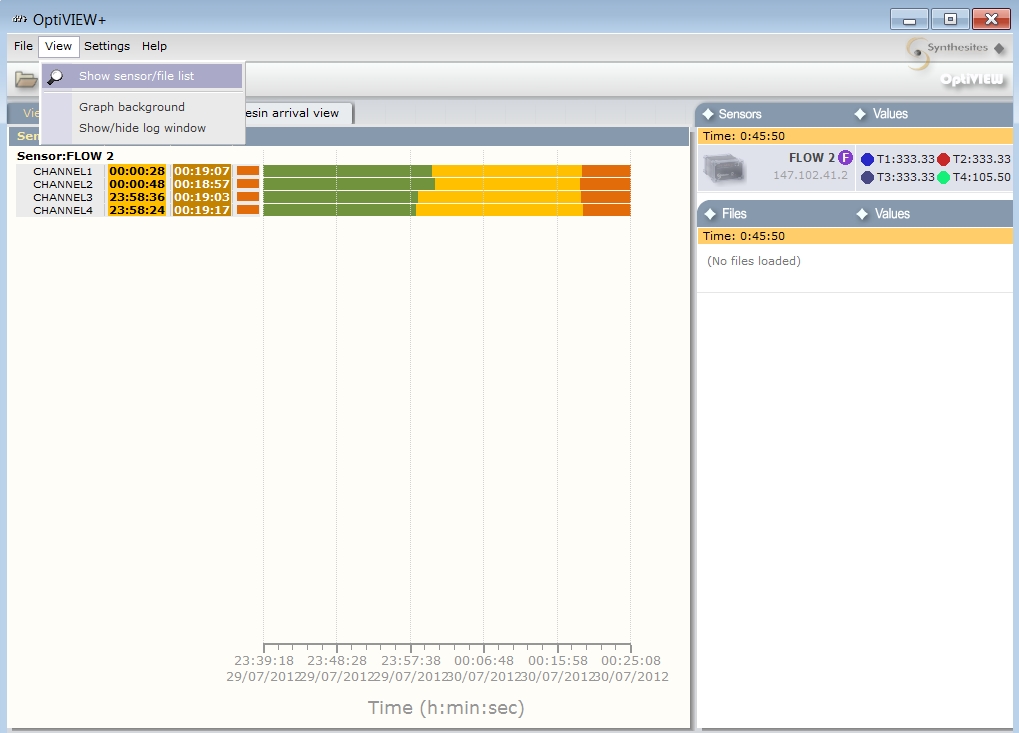

- Cure monitoring Technology

- Online Tg at DSC/DMA accuracy

- Advantages over other process monitoring technologies

- Myths about dielectric systems can measure through carbon fibres

- Myths about DC-based Dielectric cure monitoring

- Challenges when using cure kinetic models online

- Publications at Scientific Journals & Presentations at International Conferences

- Other Relevant Publications

- News & Events

- Downloads

- Contact

- Application Sectors

-